Not known Facts About Sheroz Earthworks

Not known Facts About Sheroz Earthworks

Blog Article

How Sheroz Earthworks can Save You Time, Stress, and Money.

Table of ContentsThe smart Trick of Sheroz Earthworks That Nobody is Discussing8 Simple Techniques For Sheroz EarthworksThe Basic Principles Of Sheroz Earthworks Unknown Facts About Sheroz EarthworksSheroz Earthworks - An Overview

For any earthwork contractor, it is essential to carry out work with high quality, accuracy, and on routine. Utilizing equipment control in work machines allows enhancing the various phases in the earthwork procedure, from planning to the upkeep stage - topcon laser levels. The device control system aids the device driver in acquiring the target plane promptly and easily

The device control system overviews the operator with centimeter precision. With Xsite PRO 3D, you'll always understand exactly just how much to cut or load. Your regional Xsite technical assistance can guide you and aid with any type of troubles without visiting the website. Remote support conserves money and time, as it minimizes downtime in jobsites.

The Single Strategy To Use For Sheroz Earthworks

Our system's parts are carefully designed to stand up to the rough problems of building and construction websites. Contrast of the exact same task executed making use of machine control versus the traditional approach reveals that, on average, the conventional approach needs 50% even more time to accomplish the very same task as the technology-assisted technique.

Get in the Xsite equipment control system; it's below to offer you with a significant advantage when working with earthmoving equipment. Discover exactly how Xsite Maker Control can enhance your performance and ensure job safety and security! Xsite Maker Control systems can be set up to any type of excavator from mini excavators to huge mining excavators.

Exactly how does device control job? In 2D systems, the maker is furnished with calibrated disposition sensors.

The system is extremely simple to find out the basics can be shown in under one hour of training. With Xsite you do not need to stress over learning all the suggestions and method simultaneously. Extra training and directions are always readily available over remote support when needed. Get in touch with your local Xsite dealer to discover even more! How does the remote assistance work? A wireless web link makes it feasible to establish a remote connection in between the device control system and the service.

Everything about Sheroz Earthworks

What sort of data layouts Xsite systems support? Xsite Maker Control systems sustain open conventional data layouts, allowing seamless information flow from one system to one more. Supported data formats: 2D-Maps: DXF Factor data: DXF, XML, GT, CSV, KOF, PXY Geometry lines: VGP, SBG, XML, Anpakke Surface Versions: DXF, XML What components are set up on my maker? Depending upon your option of system (with or without placing, i.e - trimble parts., 2D or 3D), your machine is geared up with inclination sensing units, a controller device, and a display/operating panel.

Several software and hardware services exist to help establish a device's current placement on the earth and compare it with a desired layout surfaceand building drivers can do even more to leverage the advantages. Device control is making use of various placing sensors and a display screen to give the operator with a reference between the position published here of the container or blade and the target grade.

Depending upon the configuration, maker control systems can provide the driver with a straightforward visual overview to bucket or blade position, or can immediately relocate the blade to quality by speaking to the device's hydraulics - https://zenwriting.net/sherozau/sheroz-earthworks-pty-ltd-and-sheroz-hire-pty-ltd-est. There are equipment control systems available for practically any type of device: , dozers, excavators, dirt and asphalt compactors, scrapes, leaners, crushing machines, and pavers

3 Easy Facts About Sheroz Earthworks Described

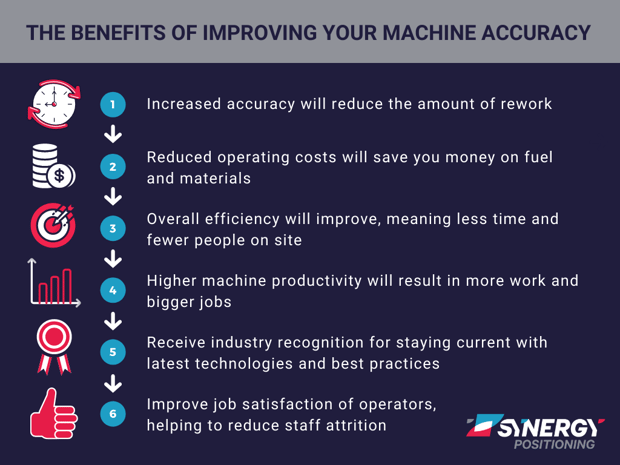

Some advantages consist of minimized rework, enhanced job efficiency, and lower checking costs. Machine control can also help raise performance and decrease general expenses. This technology is transforming the way the building market works. Building devices without machine control will certainly become a distant memory and the benefits acquired from it will certainly be countless.

Trimble device control systems supply a myriad of benefits to any individual who utilizes earthwork equipment and, at EarthCalc, we can give you with 3D data for your equipment control-enable devices. Unsure if maker control deserves the expense? Consider the complying with reasons that you need to consider this alternative.

Utilizing GPS aligned with your 3D layout documents, these systems basically ensure that you will remove or position the appropriate amount of product at the construction website. On the majority of building and construction websites, rework is a common and irritating truth, however with Trimble equipment control, you can eliminate the demand for rework.

Things about Sheroz Earthworks

Commonly, with Trimble device control, you can remove excess equipment at a certain work site. A job that could have needed the usage of 3 or 4 items of excavating equipment currently could require just 2 items of devices to achieve the very same task in less time. This allows you to relocate your tools to an additional work website and manage numerous jobs at one time.

Report this page